INSIGHTS

A Story of Unintended Consequences

Many years ago, I came across an interesting story about a plant manager who was fed up with the extremely high turnover at a factory on the border of the United States with Mexico. “I’ve had enough!”, he proclaimed against his staff’s advice, “We’ll just raise wages to be the highest in the area.” The…

Transfer of Work

Transfer of Work, or TOW, involves the movement of all products, people, materials and associated activities from one site to another. These are often manufacturing operations but can also involve service processes. When a TOW is not properly managed it can negatively impact customer service, quality, and profitability. In our recent webinar, Fidel Kandell reveals 6 groundrules for ensuring a successful…

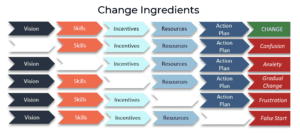

Strategy and Change Management go Hand-in-Hand!

As you hone your strategies to transform, address each of the six change ingredients to capture valueas rapidly as possible. Learn more by viewing our Change Management Webinar or continue reading! Now is the time of year when many organizations start talking strategy. Where will we grow and whatproducts, people and services do we need?…

The Power of the Elevator Speech

The Elevator Speech is a short communication moment that can be designed to deliver a key message to someone who wants to know more about your work. Whether you are introducing yourself or selling an idea, be prepared with your Elevator Speech. In our free course on the importance of developing an elevator speech, learn…

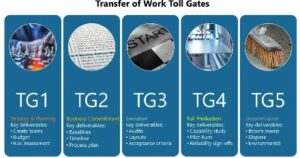

A Systematic Approach for Transferring Work

Transferring work from one site, business, or function to another can be challenging. With transfers, you can face a litany of financial, human resource, intellectual property, and operational issues. The good news is that there is a systematic approach for transferring work that can help you to ensure success. Learn how to transfer work successfully…

Demand Management for B2B

Demand Management is critical for businesses that supply goods and services to other businesses. It’s important to note that it goes beyond planning demand. In fact, there are four elements that make up Demand Management in a B2B environment. As a business matures in the journey towards excellence in Demand Management, more and more of…

Demand Management is More Critical Than Ever

It seems like everywhere we look, supply can’t keep up with demand. So why bother building an unconstrained demand forecast when the supply organization has no hope of meeting that demand? Shouldn’t we spend our time and attention on getting the supply chain right rather than bothering with the demand plan now? If your organization…

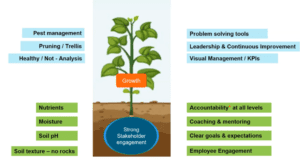

Transforming Your Team’s Culture

Tune in to this OpExecs webinar to listen to Joe Gopi, Director of Manufacturing for Sumitomo Drive Technologies and Susan Beauchamp as they share their experience with accomplishing culture change through team-based approaches. Project professionals agree – a team that is primed to question status quo and embrace innovation provides the most fertile ground for…

OpExecs Highlighted in the Chadds Ford Junction Magazine

We were recently interviewed as a local small business offering optimization support to businesses and government organizations of all shapes and sizes. Download here to read.

What is a KAIZEN event and how do you plan a VIRTUAL one?

Originally used by Toyota as part of the Toyota Production System, the Kaizen approach is used to engage front-line employees and solicit their ideas to drive change which will stick. The Kaizen Process enables ‘change for the better’ The term “Kaizen” is another way to describe continuous improvement or change for the better. As an…